Walkthrough: Performing an Expired Inventory Quality Audit

In this walkthrough, you will learn what needs to be set up in order to execute an Expired Inventory quality audit, and what happens during that quality audit.

An Expired Inventory quality audit is when a series of tests need to be performed on items that have expired, or that have an arbitrary expiry date and need to be checked to see if the expiry date can be extended.

Function Background

With quality audits, you first need to set up the quality measures and quality procedures.

Quality measures are individual checks that need to be completed in a quality audit. Quality measure codes are assigned to quality procedures. The same quality measure code can be assigned to multiple quality procedures.

A quality procedure is a grouping of quality measure codes. The quality procedure can then be set up so that when an event occurs, a unique quality audit is generated based on that quality procedure. The same quality procedure can be associated with different events but a unique quality audit will always be generated when the event occurs.

Story

In the JF company, flour is not considered to have an expiry date. But to ensure that quality is maintained, a quality audit is performed on the flour at six month intervals. When flour is received, it is given an expiry date of 6 months. On a weekly basis, the JF Company runs the Inventory Expiry Analysis report to see what items are expired or almost expired. When the flour appears on the report, the JF Company can then run the associated quality audit to check that the flour is still in good condition.

During the quality audit, the JF company will check the moisture for ORGANIC ENR WHEAT FLOUR (R100320).

Prerequisites

Number series defined for the Quality Procedure Setup Nos. field on the Quality Setup page.

Number series defined for the Quality Audit Nos. field on the Quality Setup page.

Expired inventory exists

Setting up an Expired Inventory Quality Audit

The following procedures explain what needs to be set up in order to process an Expired Inventory quality audit:

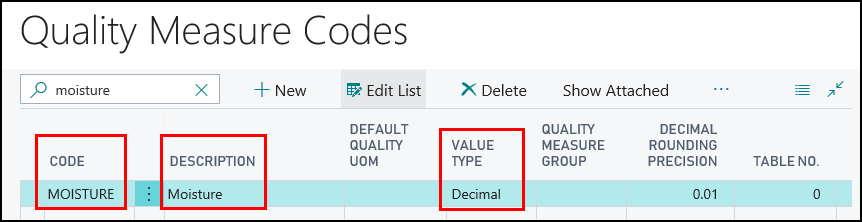

To create quality measure codes

The quality measure codes represent the different ways of recording the quality of an item. Quality measure codes need to be created for each of the conditions that need to be checked or tested.

For the JF company, that means that a quality measure code needs to be created for MOISTURE.

You can skip this step if the MOISTURE code already exists in your company.

Choose the

icon, enter Quality Measure Codes, and then choose the related link.

icon, enter Quality Measure Codes, and then choose the related link.On the Quality Measure Codes page, choose the New action.

Add the following record:

Code Description Value Type MOISTURE Moisture Decimal

Close the page.

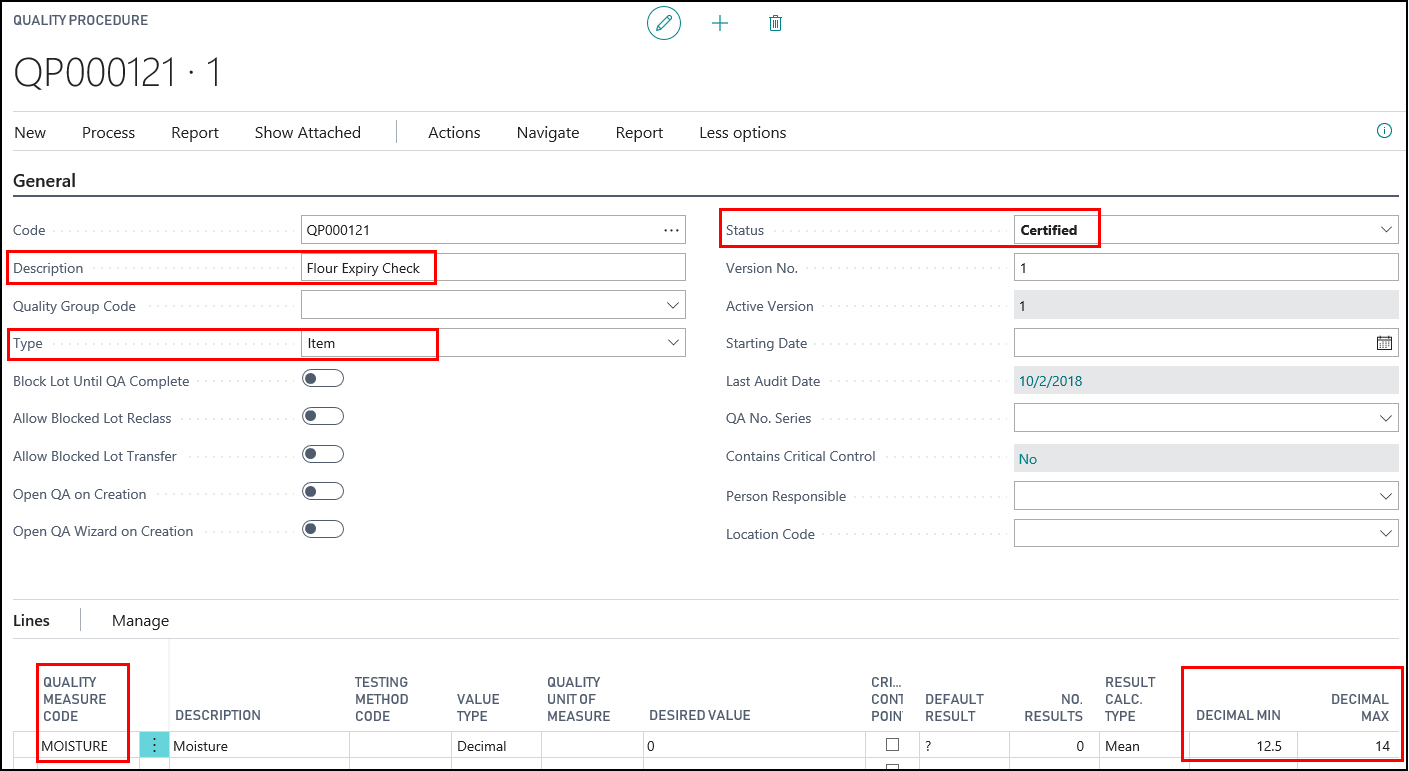

To create a quality procedure

A quality procedure groups quality measure codes, and allows you to record the desired test results. The quality procedure can then be assigned to an item. When an item is manufactured or output, the quality procedure is used to create a quality audit related to the expired item.

For the JF company, a Flour Expiry Check quality procedure is being created. This quality procedure will be used to generate a quality audit that will be used to check a sample of the flour.

Choose the

icon, enter Quality Procedures, and then choose the related link.

icon, enter Quality Procedures, and then choose the related link.On the Quality Procedures page, choose the New action.

On the Quality Procedure page, enter information on the General FastTab.

Description: Enter Flour Expiry Check.

Type: Select Item.

Add the following record to the Lines FastTab.

| Quality Measure Code | Decimal Min | Decimal Max |

|---|---|---|

| MOISTURE | 12.5 | 14 |

On the General FastTab, change the Status field to Certified.

Close the page.

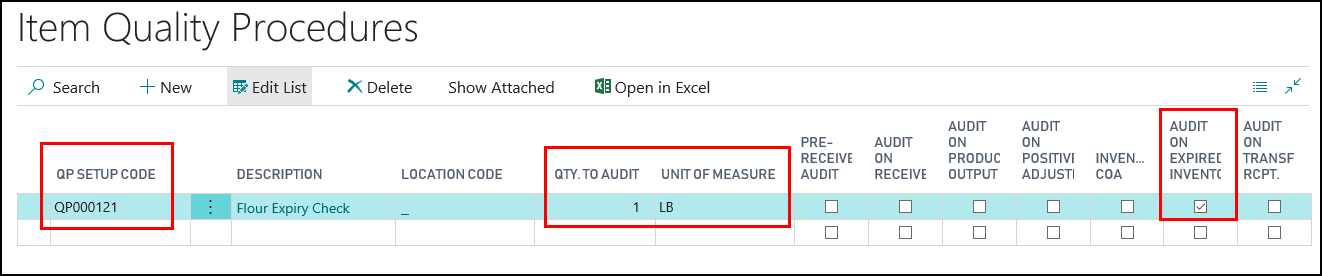

To assign the quality procedure to an item

The Flour Expiry Check quality procedure needs to be assigned to the flour products. In this walkthrough, the quality procedure is being assigned to the ORGANIC ENR WHEAT FLOUR (R100320) item.

Once a procedure is assigned to an item, an Expired Inventory quality audit can be generated from the QA Planning Worksheet page. When the quality audit is performed, a 1 pound sample should be tested.

Choose the

icon, enter Items, and then choose the related link.

icon, enter Items, and then choose the related link.Open the item that you want to assign the quality procedure to. In this case, R100320 ORGANIC ENR WHEAT FLOUR.

On the Item Card page, choose the Quality Procedures action.

On the Item Quality Procedures page, Add a line for the Flour Expiry Check quality procedure.

QP Setup Code: Enter Flour Expiry Check, and select the quality procedure that you created.

Qty. to Audit: Enter 1.

Unit of Measure: Select LB.

Audit on Expired Inventory: Select the check box.

Close the Item Quality Procedures page.

Close the Item Card page.

Generating an Expired Inventory Quality Audit

This section contains the following procedures:

Prerequisites

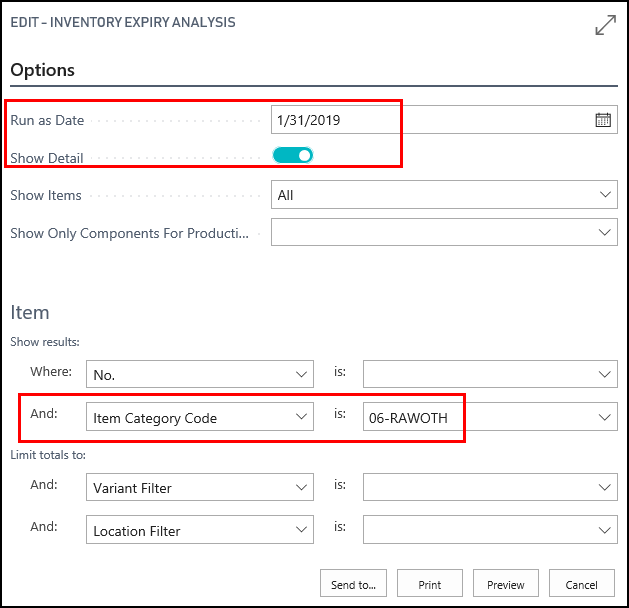

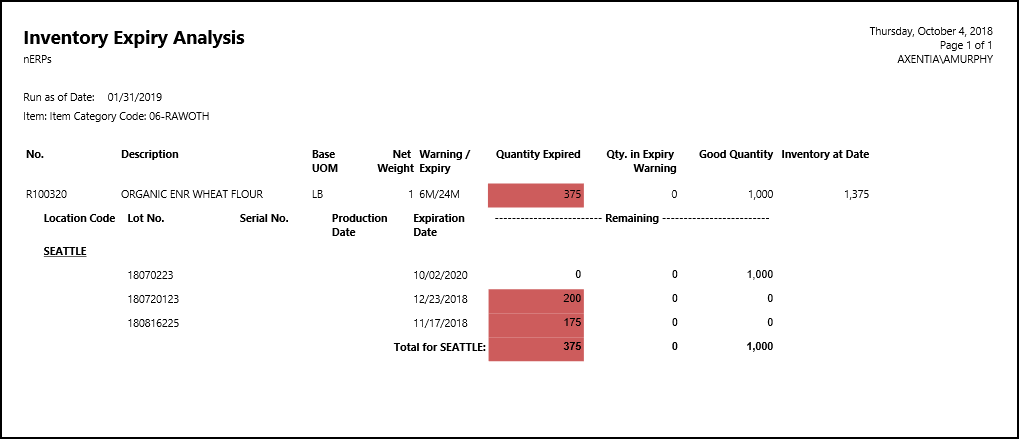

To run an inventory expiry analysis report

The Inventory Expiry Analysis report is used to identify items that are expired or almost expired. The JF Company has a process in place where the report is run on a weekly basis. Quality audits can then be generated as required.

Choose the

icon, enter Inventory Expiry Analysis, and then choose the related link.

icon, enter Inventory Expiry Analysis, and then choose the related link.In the Run as Date field, select the date that you want the report to run as. In this case, 1/31/2019.

Select the Show Detail check box.

In the Filters field, select a value for the Item Category Code. In this case, 06-RAWOTH.

Click Preview.

The report is generated for all of the items where the Item Category Code is 06-RAWOTH.

Items that have expired goods are highlighted in red. The ORGANIC ENR WHEAT FLOUR (R100320) item is showing as expired.

Close the Inventory Expiry Analysis Report.

To generate an expired inventory quality audit

Choose the

icon, enter Quality Audit Planning Worksheet, and then choose the related link.

icon, enter Quality Audit Planning Worksheet, and then choose the related link.On the Quality Audit Planning Worksheet page, select a value in the Batch Name field.

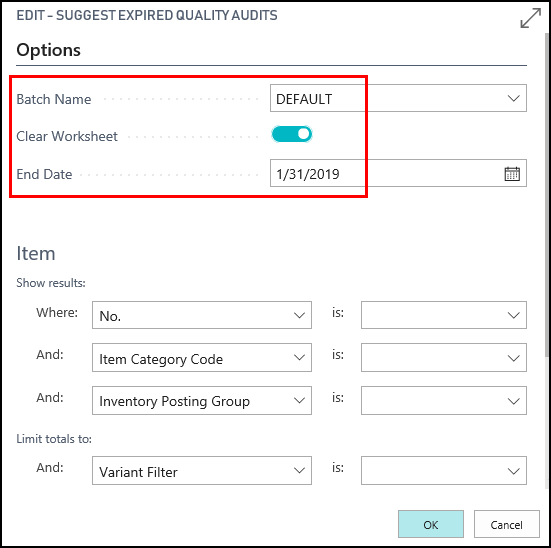

Choose the Suggest Quality Audits action.

Select Expired Inventory.

On the Suggest Quality Audits page, select the Clear Worksheet check box.

In the End Date field, enter the last date that you want the report to look for expired items.

Click OK.

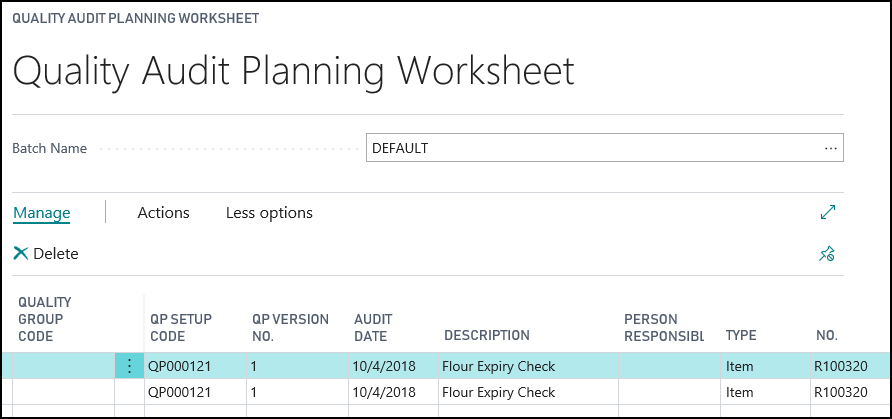

Lines are returned for items that have a blank expiry date, or an expiry date on or before the end date that was entered, AND that have an associated quality procedure where Audit on Expired Inventory was selected.

Delete any lines for which you do not want to create quality audits.

In this case, both lines will be kept.

On the Quality Audit Planning Worksheet page, choose the Create Quality Audits action.

Click Yes to create an audit from the QA Planning Worksheet.

A quality audit is created. The Quality Audit page does not automatically open because the Open QA on Creation check box was not selected for the Flour Expiry Check quality procedure.

Close the Quality Audit Planning Worksheet page.

To view the quality audit

Choose the

icon, enter Items, and then choose the related link.

icon, enter Items, and then choose the related link.Open the item that has the associated quality audit.

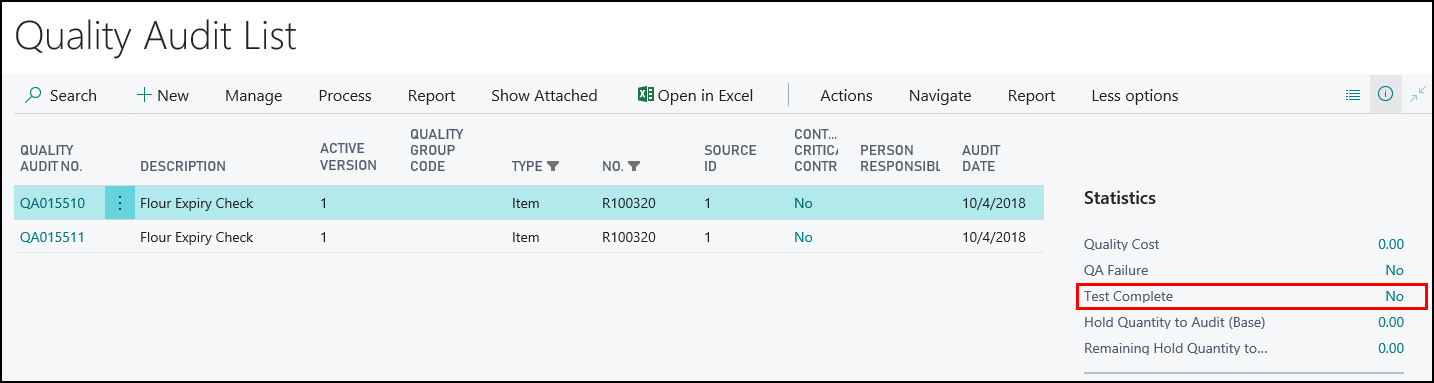

On the Item Card page, choose the Quality Audits action.

All of the open quality audits for the item are listed

The Test Complete field in the Statistics FactBox shows that the quality audit has not been completed.

On the Quality Audit List, click the Quality Audit No.

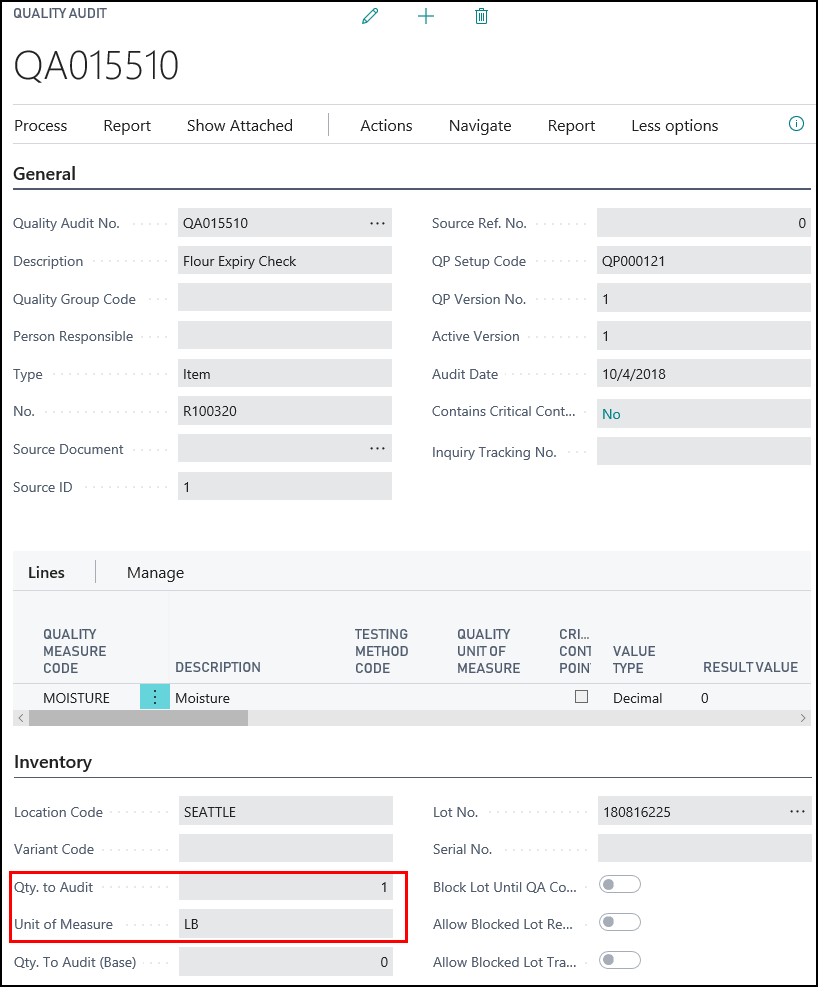

The Quality Audit page opens, which shows the tests/measures that need to be completed. The Inventory FastTab shows that 1 pound should be tested.

Performing the Expired Inventory Quality Audit

The JF Company can test one pound of the ORGANIC ENR WHEAT FLOUR (R100320) item, lot 180816225, and when it passes the audit, the expiry date for that lot can be changed to six months in the future (since the flour is tested every six months).

To perform a quality audit

Complete the steps in To view the quality audit.

On the Quality Audit page, choose the Quality Audit Wizard.

On the Quality Audit Wizard page, click Next.

Enter the results of the moisture test.

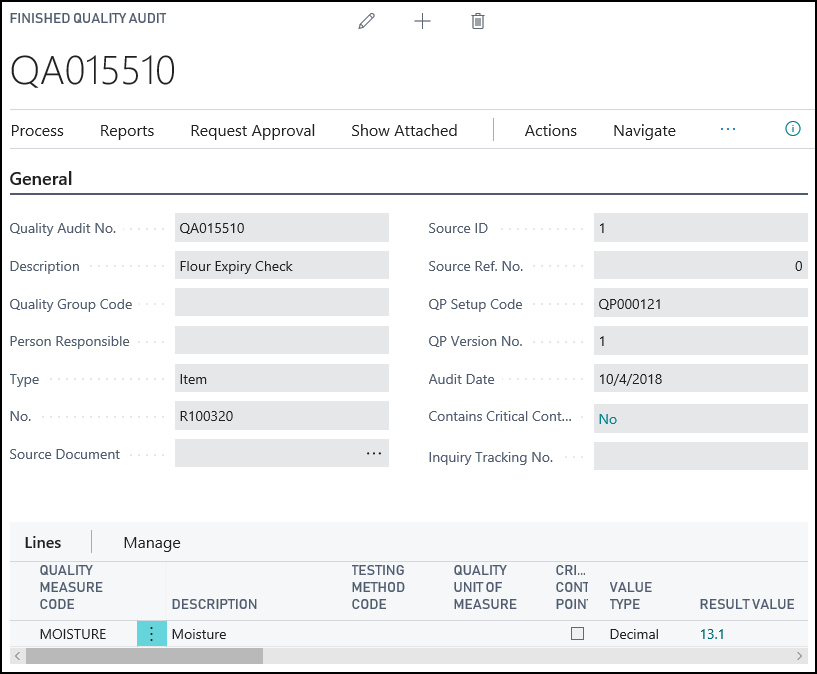

In the Result Value field, enter 13.1.

The Result field is automatically populated with Pass. The Test Complete check box is automatically selected.

Click Next.

Finish the audit.

Select the Post audit on Finish check box.

Select the Close wizard on Finish check box.

Click Finish.

The quality audit is posted.

Close the Quality Audit List page.

To view the posted quality audit

Once the production order is finished, you can view the finished quality audit from the Item Card page.

Choose the

icon, enter Items, and then choose the related link.

icon, enter Items, and then choose the related link.Open the item that has the posted quality audit.

On the Item Card page, choose the Finished Quality Audits action.

All of the finished quality audits for the item are listed

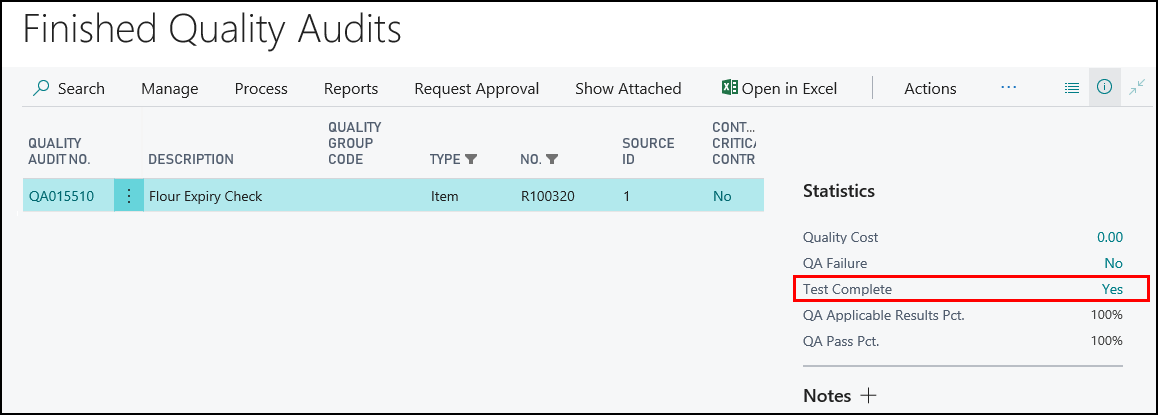

The Test Complete field in the Statistics FactBox shows that the quality audit has been completed.

On the Finished Quality Audits page, click the Quality Audit No.

Video

See Also

About Quality

Quality Management Walkthroughs

JustFood Walkthroughs