Walkthrough: Performing a Manufacturing Quality Audit

In this walkthrough, you will learn what needs to be set up in order to execute a Manufacturing quality audit, and what happens during that quality audit.

A Manufacturing quality audit is when a series of tests need to be performed on items that have been manufactured.

Function Background

With quality audits, you first need to set up the quality measures and quality procedures.

Quality measures are individual checks that need to be completed in a quality audit. Quality measure codes are assigned to quality procedures. The same quality measure code can be assigned to multiple quality procedures.

A quality procedure is a grouping of quality measure codes. The quality procedure can then be set up so that when an event occurs, a unique quality audit is generated based on that quality procedure. The same quality procedure can be associated with different events but a unique quality audit will always be generated when the event occurs.

Story

The JF company is manufacturing 25 cases of YOGIES Milk Chocolate Pretzels (F100020). Once the item has been output, the following tests need to be performed on a sample item.

Package check

Net weight of the case

Until the tests are performed, the manufactured items cannot be picked for a sales order.

Prerequisites

Number series defined for the Quality Procedure Setup Nos. field on the Quality Setup page.

Number series defined for the Quality Audit Nos. field on the Quality Setup page.

Manufactured item exists with a Bill of Materials (BOM) and routing.

Setting up a Manufacturing Quality Audit

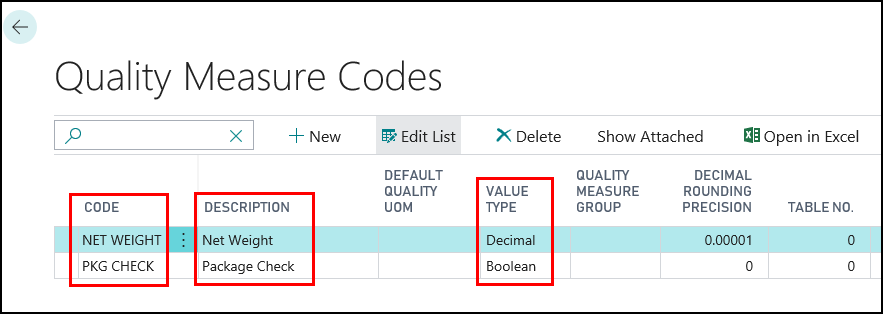

To create quality measure codes

The quality measure codes represent the different ways of recording the quality of an item. Quality measure codes need to be created for each of the conditions that need to be checked or tested.

For the JF company, that means that quality measure codes need to be created for the following:

- Package check

- Net weight

You can skip this step if the quality measure codes already exist in your company.

Choose the

icon, enter Quality Measure Codes, and then choose the related link.

icon, enter Quality Measure Codes, and then choose the related link.On the Quality Measure Codes page, choose the New action.

Add the following records:

Code Description Value Type NET WEIGHT Net Weight Decimal PKG CHECK Package Check Boolean

Close the Quality Measure Codes page.

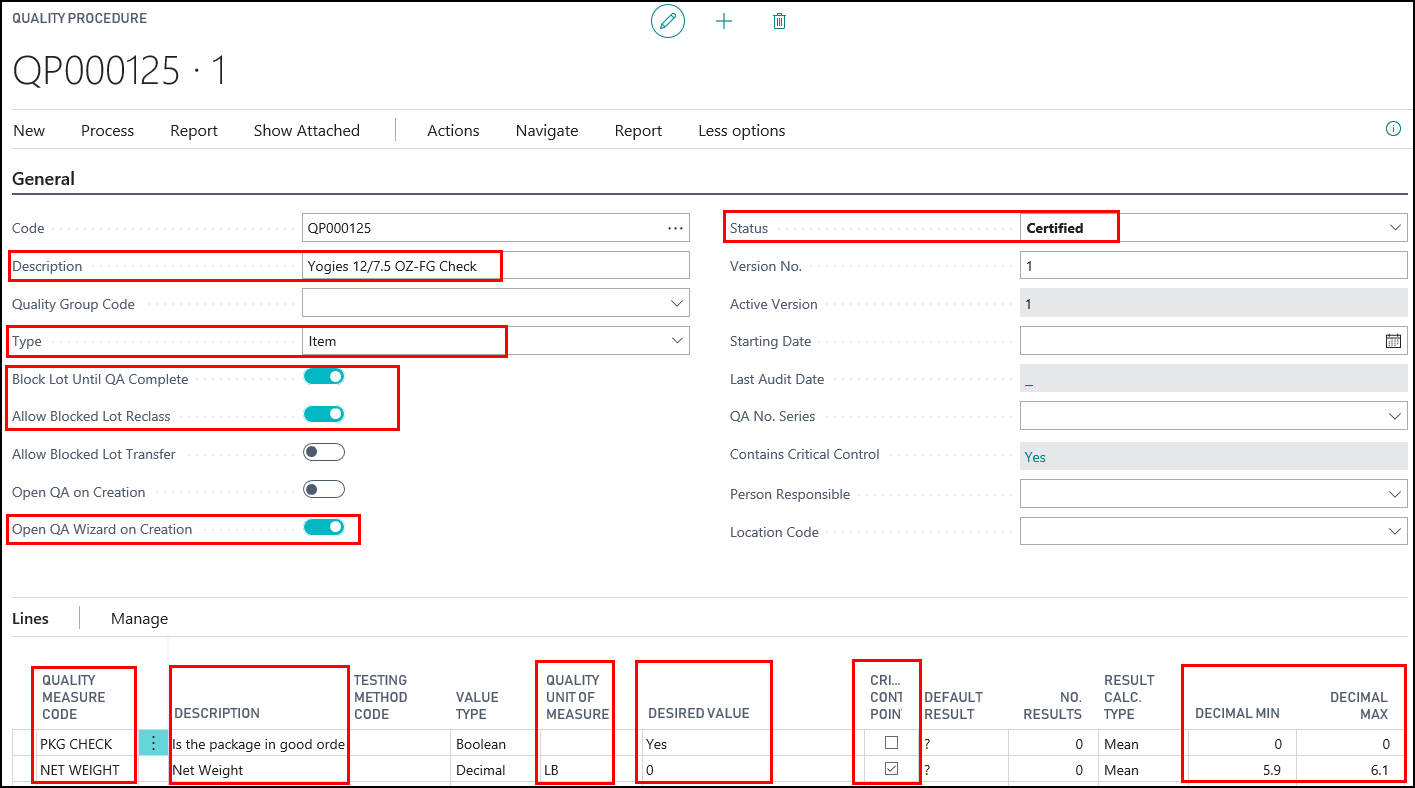

To create a quality procedure

A quality procedure groups quality measure codes, and allows you to record the desired test results. The quality procedure can then be assigned to an item. When an item is manufactured or output, the quality procedure is used to create a quality audit related to the manufactured item.

For the JF company, a Yogies 12/7.5 OZ-FG Check quality procedure is being created. This quality procedure will be used to generate a quality audit that will check a case of YOGIES items. The case contains twelve 7.5 OZ packages of YOGIES.

Choose the

icon, enter Quality Procedures, and then choose the related link.

icon, enter Quality Procedures, and then choose the related link.On the Quality Procedures page, choose the New action.

On the Quality Procedure page, enter information on the General FastTab.

Description: Enter Yogies 12/7.5 OZ-FG Check.

Type: Select Item.

Block Lot Until QA Complete: Select the check box.

This prevents transactions from occurring with this item’s lot until the quality audit is completed and passed.

Allow Blocked Lot Reclass: Select the check box.

This allows blocked lots to be moved within a location.

Open QA Wizard on Creation: Select the check box.

This opens the QA Wizard page once the quality audit is created. The QA Wizard allows users to enter the test results.

Add the following records to the Lines FastTab.

Quality Measure Code Description Value Type Quality Unit of Measure Desired Value Decimal Min Decimal Max Critical Control Point PKG CHECK

Is the package in good order?

Boolean

Yes

0

0

NET WEIGHT

Decimal

LB

5.9

6.1

Checked

On the General FastTab, change the Status field to Certified.

Close the Quality Procedure page.

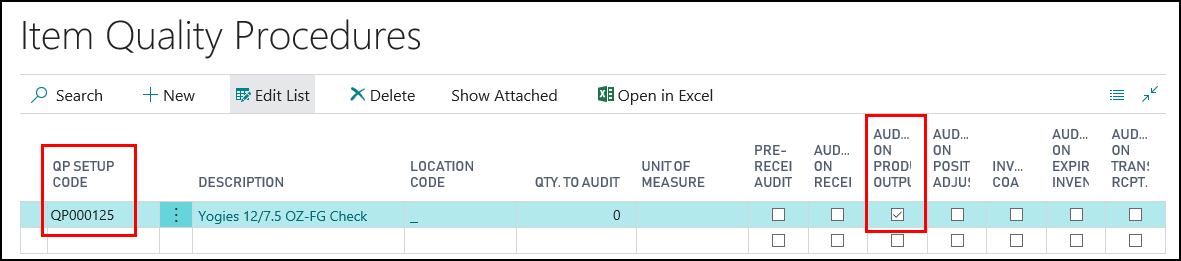

To assign the quality procedure to an item

The Yogies 12/7.5 OZ-FG Check quality procedure needs to be assigned to the YOGIES 12/7.5 OZ MK CHOC PRTZL (F100020) item. When the item is manufactured, a Manufacturing quality audit will be automatically created based on the assigned quality procedure.

Choose the

icon, enter Items, and then choose the related link.

icon, enter Items, and then choose the related link.Open the item that you want to assign the quality procedure to. In this case, F100020 YOGIES 12/7.5 OZ MK CHOC PRTZL.

On Item Card page, choose the Quality Procedures action.

On the Item Quality Procedures page, populate the following fields:

QP Setup Code: Select the Yogies 12/7.5OZ-FG Check quality procedure that you created.

Audit on Production Output: Select the check box.

Close the Item Quality Procedures page.

Close the Item Card page.

Generating a Manufacturing Quality Audit

Prerequisites

A released production order was created for the item associated with the Manufacturing quality audit. In this case, YOGIES 12/7.5 OZ MK CHOC PRTZL (F100020).

To generate a manufacturing quality audit

Choose the

icon, enter Released Production Orders, and then choose the related link.

icon, enter Released Production Orders, and then choose the related link.Open the released production order that was created for the item associated with the Manufacturing quality audit.

From the Lines FastTab, choose the Line>Production Journal action.

On the Production Journal page, delete the consumption lines.

NOTE

This walkthrough is an example only, and the Consumption lines are being deleted to simplify the walkthrough. Your company processes may dictate that the Consumption lines remain.

Ensure the Output Quantity field is populated.

Assign a lot number to the item.

Select the Output line.

Choose the Item Tracking Lines action.

On the Item Tracking Lines page, choose the Assign Lot No. action.

Close the Item Tracking Lines page.

On the Production Journal page, choose the Post action.

Click Yes to post the journal lines.

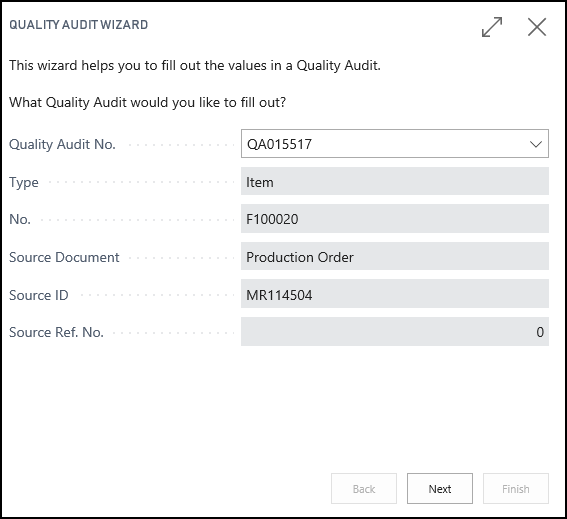

Click OK at the message that a quality audit was created.

The Quality Audit Wizard page automatically opens because the Open QA Wizard on Creation check box was selected for the quality procedure that is associated with the YOGIES 12/7.5 OZ MK CHOC PRTZL (F100020) item.

Click OK at the message that the journal lines were successfully posted.

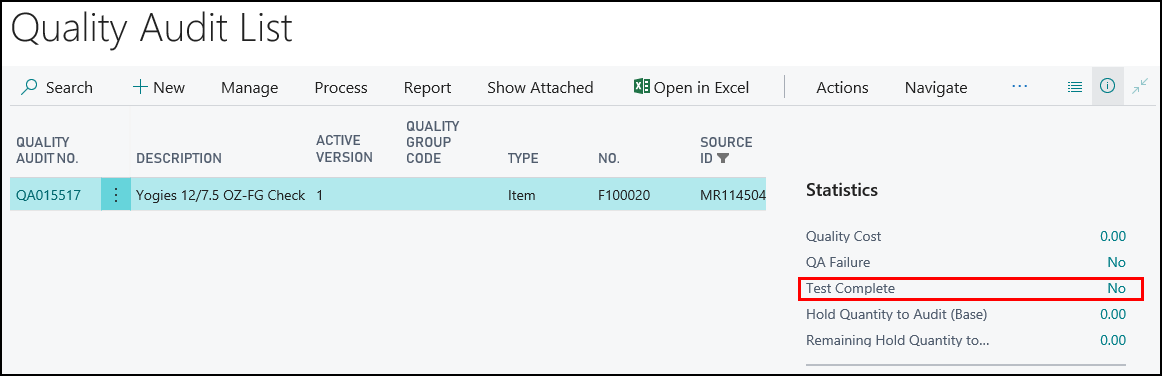

To view the quality audit

You can access the Manufacturing Inventory quality audit from several places:

Quality Audits action on the Released Production Order page.

Quality Audits action on the Item Card page (all of the open quality audits for the item are listed).

The Test Complete field in the Statistics FactBox shows that the quality audit has not been completed.

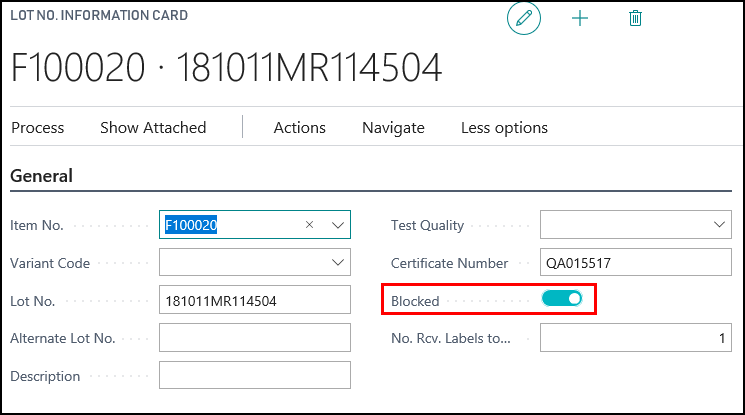

To view that the lot is blocked

When setting up the Yogies 12/7.5 OZ-FG Check quality procedure, the Block Lot Until QA Complete check box was selected, which means that the lot associated with the open quality audit is blocked until quality audit is completed.

Choose the

icon, enter Items, and then choose the related link.

icon, enter Items, and then choose the related link.Open the item card for the item associated with the Manufacturing quality audit. YOGIES 12/7.5 OZ MK CHOC PRTZL (F100020).

On the Item Card page, choose the Ledger Entries action.

On the Item Ledger Entries page, select the line that contains the lot number that was manufactured.

Choose the Lot No. Information action.

You can see that the lot is blocked.

Performing the Manufacturing Quality Audit

Before the YOGIES 12/7.5 OZ MK CHOC PRTZL (F100020) item can be picked for a sales order, the item needs to pass the associated quality audit.

To perform a quality audit

NOTE

If the Quality Audit Wizard page is already open, go to step 6.

Choose the

icon, enter Items, and then choose the related link.

icon, enter Items, and then choose the related link.Open the item card for the item associated with the Manufacturing quality audit. YOGIES 12/7.5 OZ MK CHOC PRTZL (F100020).

On the Item Card page, choose the Quality Audits action.

Open the quality audit.

On the Quality Audit page, choose the Quality Audit Wizard action.

On the Quality Audit Wizard page, click Next.

Enter if the package is in good condition.

In the Result Value field, enter Yes. The Result field is automatically populated with Pass. The Test Complete check box is automatically selected.

Click Next.

Enter the weight of the case.

In the Result Value field, enter 6. The Result field is automatically populated with Pass. The Test Complete check box is automatically selected.

Click Next.

Finish the audit.

Select the Post audit on Finish check box.

Select the Close wizard on Finish check box.

Click Finish.

The quality audit is posted. The YOGIES 12/7.5 OZ MK CHOC PRTZL (F100020) item can now be picked for a sales order.

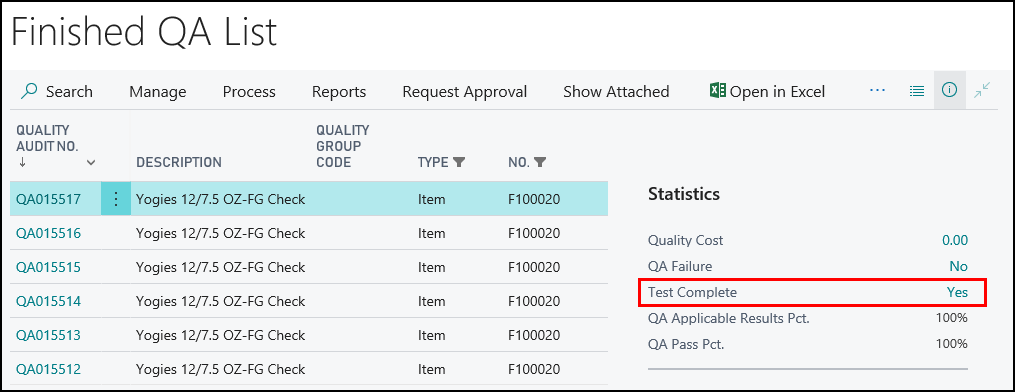

To view the posted quality audit

Once the production order is finished, you can view the finished quality audit from several places:

Finished Quality Audits action on the Finished Production Order page

Finished Quality Audits action on the Item Card page (all of the finished quality audits for the item are listed)

The Test Complete field in the Statistics FactBox shows that the quality audit has been completed.

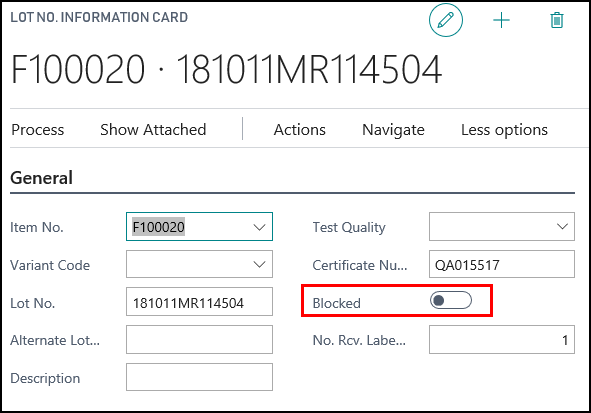

To view that the lot is no longer blocked

Since the quality audit associated with the YOGIES 12/7.5 OZ MK CHOC PRTZL (F100020) item has passed and has been completed, the lot is no longer blocked.

Choose the

icon, enter Items, and then choose the related link.

icon, enter Items, and then choose the related link.Open the item card for the item associated with the Manufacturing quality audit. YOGIES 12/7.5 OZ MK CHOC PRTZL (F100020).

On the Item Card page, choose the Ledger Entries action.

On the Item Ledger Entries page, select the line that contains the lot number that was manufactured.

Choose the Lot No. Information action.

You can see that the lot is no longer blocked.

Video

See Also

About Quality

Quality Management Walkthroughs

JustFood Walkthroughs