Walkthrough: Placing an Item on Quality Hold

In this walkthrough, you will learn how to put an item on a quality hold, and then release the item from the quality hold.

An item that has been put on a quality hold is not considered to be in inventory, and will not be part of an availability calculation. A quality hold is often used for damaged items.

Function Background

The Quality Hold Journal is used to put items on hold. Items can be put on hold based on location, lot number, bin code, container number and/or serial number.

Items on hold can be moved within a location using the Item Reclass. Journal page or the Floor application.

A Quality Hold Valuation report can be run, which shows the location, lot number, cost and quantity of the items on hold.

Story

The roof leaked at the JF Company, and 6 cases of YOGIES 12/5 OZ MILK CHOC PRTZL (F100040) LOT0000307, in the OUTBOUND bin, appear to be damaged. The 6 cases are put on hold. Upon inspection, 2 of the cases were found to be undamaged, and were released back in to inventory. The remaining 4 damaged cases are moved to the DAMAGES bin.

Prerequisites

Reason codes are defined.

Number series defined for quality holds on the No. Series page.

Inventory exists in a bin. In this case, 6 cases of the YOGIES 12/5 OZ MILK CHOC PRTZL (F100040) item are in the OUTBOUND bin at the SEATTLE location.

A bin exists where you're going to move your damaged items. In this case, the DAMAGES bin at the SEATTLE location.

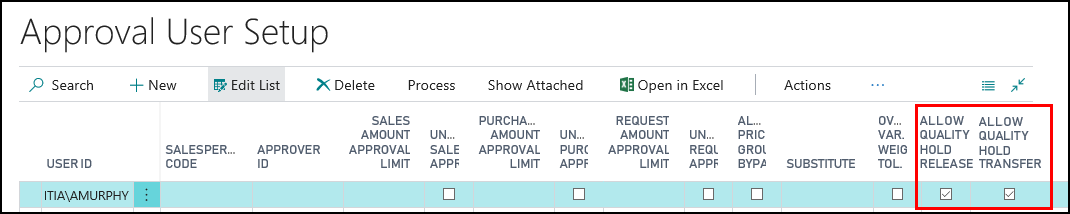

Setting Up Quality Hold Permissions

Choose the

icon, enter Approval User Setup, and then choose the related link.

icon, enter Approval User Setup, and then choose the related link.If required, choose New to add a user.

Populate the following fields for the user who will be managing quality holds. In this case, ADMIN.

Allow Quality Hold Release: Select the check box.

This allows the user to release items that are on quality hold.

Allow Quality Hold Transfer: Select the check box.

This allows the user to move items on quality hold using the Item Reclass. Journal or the Floor application.

Close the Approval User Setup page.

Placing an Item on Hold

Choose the

icon, enter Quality Hold Journal, and then choose the related link.

icon, enter Quality Hold Journal, and then choose the related link.Create a new batch name:

Click the Look up value button beside the Batch Name field.

On the Quality Hold Batches page, choose the New action.

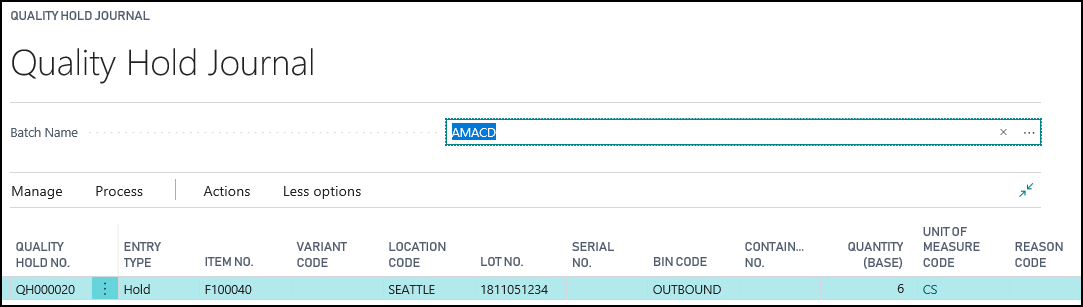

In the Name field, enter AMACD, which is part of the Quality Control Inspector's name.

In the Description field, enter A Macdonald-Inspector.

Leave the Reason Code field blank.

In the No. Series field, select QHJNL.

Click OK.

On the Quality Hold Journal page, delete any existing lines.

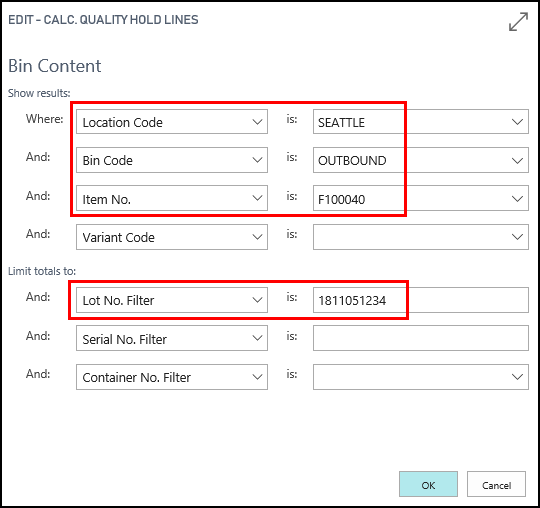

Choose the Calc. Quality Hold Lines action.

On the Calc. Quality Hold Lines page, populate the following fields, and then click OK.

Location Code: Select the location that contains the item to put on hold.

Bin Code: Select the bin code that contains the item to put on hold.

Item No.: Select the item that you want to put on hold.

Lot No.: Enter the lot number of the damaged item.

Matching records are returned to the Quality Hold Journal.

On the Quality Hold Journal page, delete any lines that contains that you do not want to put on hold.

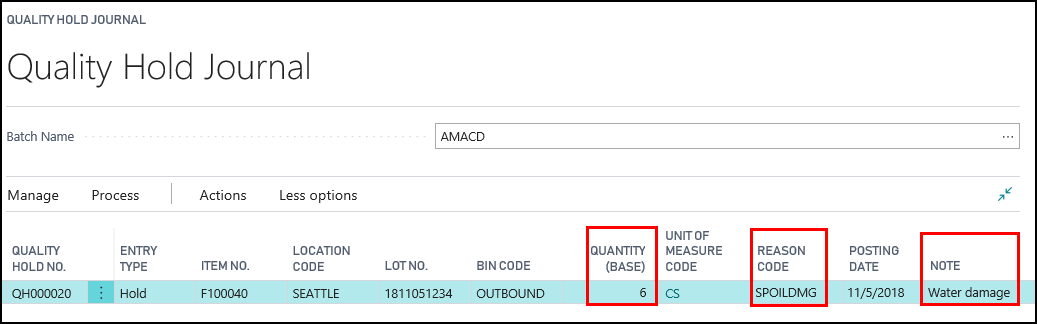

Populate the following fields:

Quantity (Base): Change the value to 6.

Reason Code: Select SPOILDMG.

Note: Enter Water damage.

Choose the Post action.

Click Yes to post the journal lines.

Click OK.

The quality hold journal lines are deleted.

The item quantity specified on the journal line is now on a quality hold and removed from available inventory.

Close the Quality Hold Journal page.

Viewing the Item on Hold

Choose the

icon, enter Items, and then choose the related link.

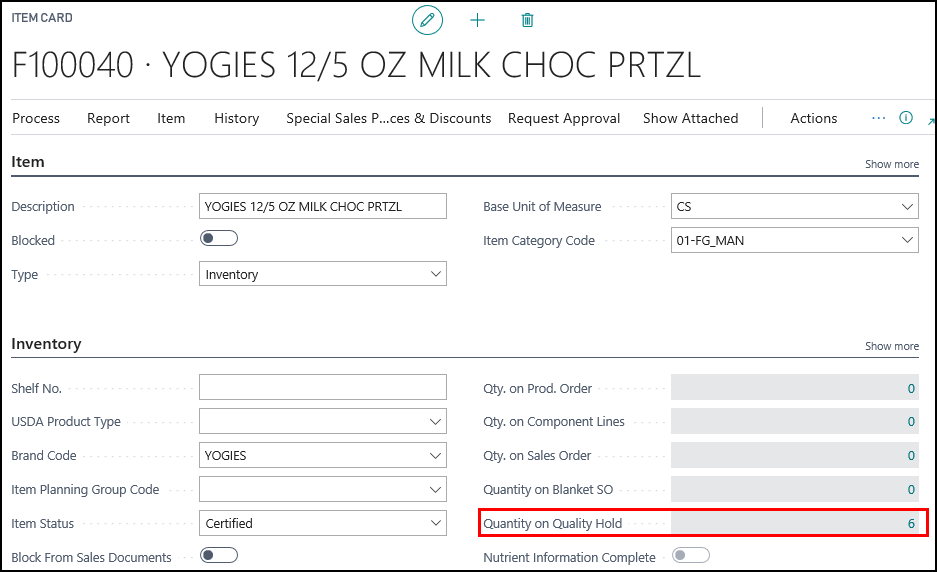

icon, enter Items, and then choose the related link.Open the item card for the item that was put on hold. In this case, YOGIES 12/5 OZ MILK CHOC PRTZL (F100040) item.

The Quantity on Quality Hold field shows the number of items that are on hold.

Click the Quantity on Quality Hold value.

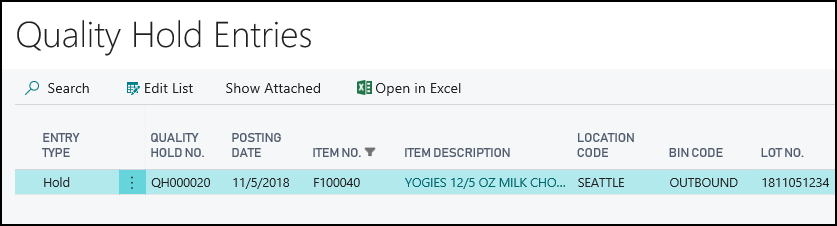

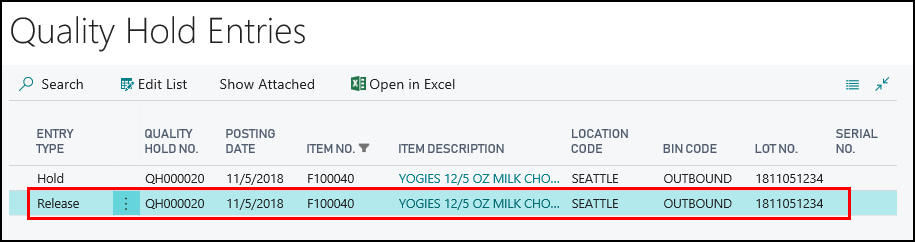

The Quality Hold Entries page shows the details of the quality hold.

Close the Quality Hold Entries page.

Close the Item Card page.

Releasing Items on Hold

After inspecting the damaged cases of the YOGIES 12/5 OZ MILK CHOC PRTZL (F100040) item, the quality processor found that only 4 cases were damaged instead of the 6 cases first put on hold. As a result, the other 2 cases can be released back in to inventory.

A user must have permission to release items on quality hold. See Set up Quality Hold Permissions.

Choose the

icon, enter Quality Hold Journal, and then choose the related link.

icon, enter Quality Hold Journal, and then choose the related link.On the Quality Hold Journal page, select a batch name.

Delete any existing lines.

Choose the Get QH Release Lines action.

On the Get QH No. Contents page, enter the quality hold number in the Quality Hold No. field.

Alternatively, you could select the item number and lot number.

Click OK.

Matching records are returned to the Quality Hold Journal.

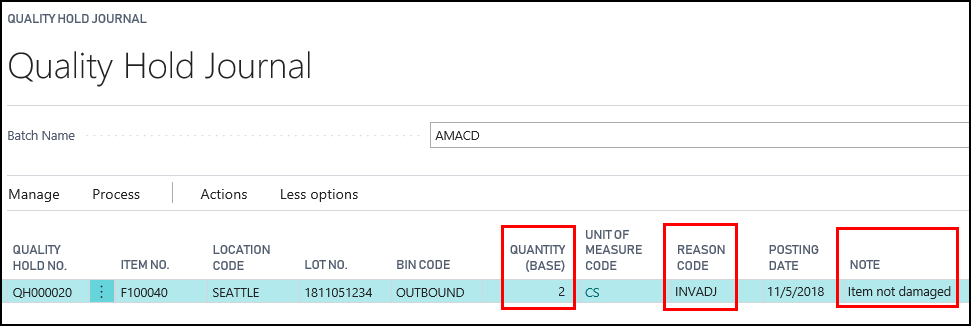

On the Quality Hold Journal page, populate the following fields:

Quantity (Base): Enter 2. Only 4 cases were damaged so the remaining 2 can be released back in to inventory.

Reason Code: Select INVADJ (Inventory Adjustment).

Note: Enter Item not damaged. This is the reason the item is being released from the quality hold.

On the Actions tab, choose Post.

Click Yes to post the journal line.

Click OK that the journal lines were successfully posted.

The quality hold journal lines are deleted.

The item quantity specified on the journal line is now removed from the quality hold, and placed into available inventory.

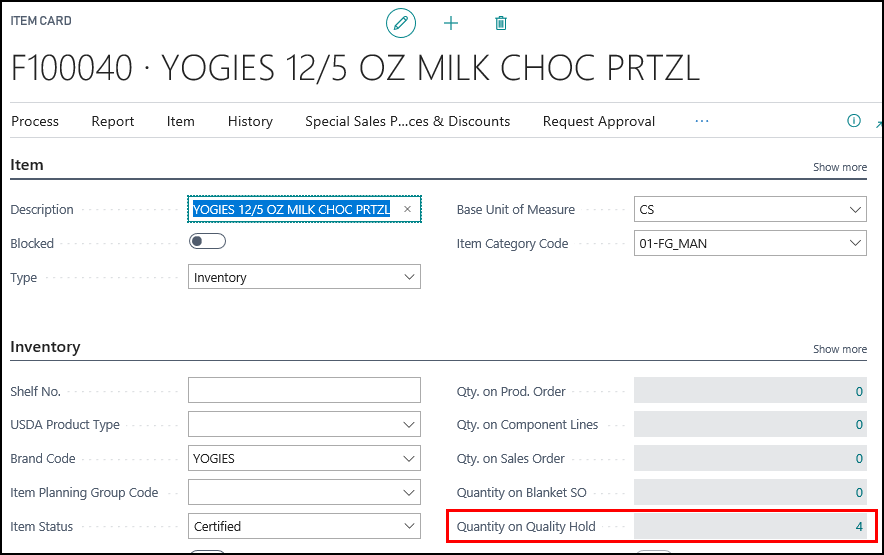

The Item Card shows the new quality hold quantity as 4.

The Quality Hold Entries page now shows the Release record.

Close the Quality Hold Entries page.

Moving Items on Hold

The damaged items need to be moved out of the OUTBOUND bin and into the DAMAGES bin.

A user must have permission to move items on quality hold. See Set up Quality Hold Permissions.

Choose the

icon, enter Item Reclassification Journals, and then choose the related link.

icon, enter Item Reclassification Journals, and then choose the related link.On the Item Reclassification Journals page, delete any existing lines.

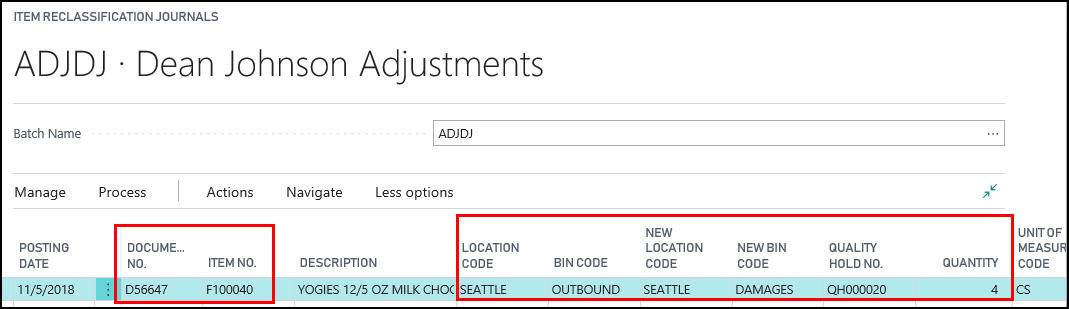

Populate the following fields:

Document No.: Enter a document number.

Item No.: Select F100040.

Location Code: Select SEATTLE.

Bin Code: Select OUTBOUND.

New Bin Code: Select DAMAGES.

Quality Hold No.: Select the quality hold number.

Quantity: Enter 4. This is the number of items that you want to move.

Choose the Item Tracking Lines action.

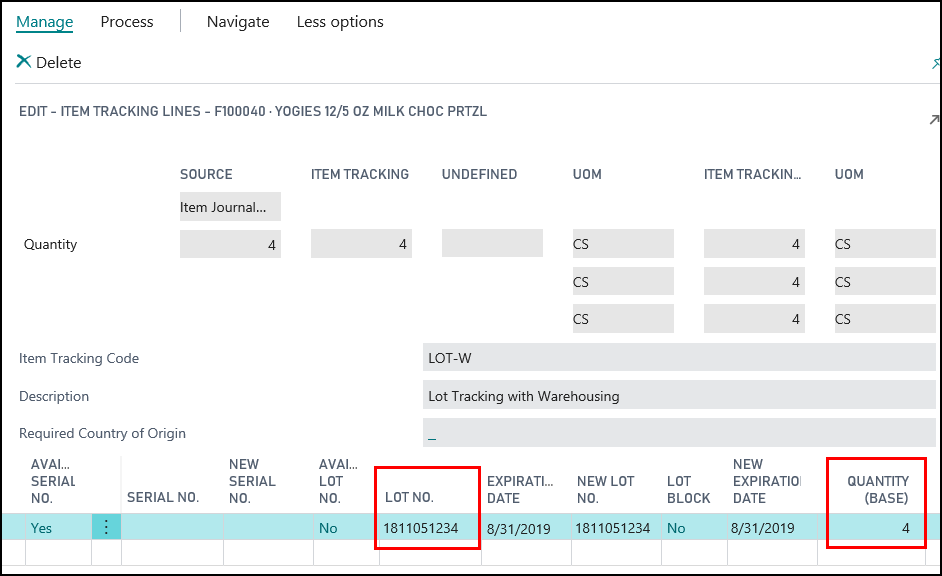

On the Item Tracking Lines page, populate the following fields:

Lot No.: Select the lot number of the item that is on hold.

Quantity (Base): Enter 4.

Click Close.

Click Yes at the availability warnings message.

The Tracking Status field on the Item Reclass. Journal is changed to FILLED.

On the Item Reclass. Journal page, choose the Post action.

Click Yes to post the journal line.

The 4 damaged cases are moved to the DAMAGES bin.

Video

See Also

About Quality

Quality Management Walkthroughs

JustFood Walkthroughs