Walkthrough: Production Order Linking

The following walkthrough is an example of how the Scheduler works when a production order is linked to one or more different production orders. This walkthrough applies in cases where you have a finished good item that includes a WIP item. The WIP item must be complete before production can begin on the finished good item.

Walkthrough

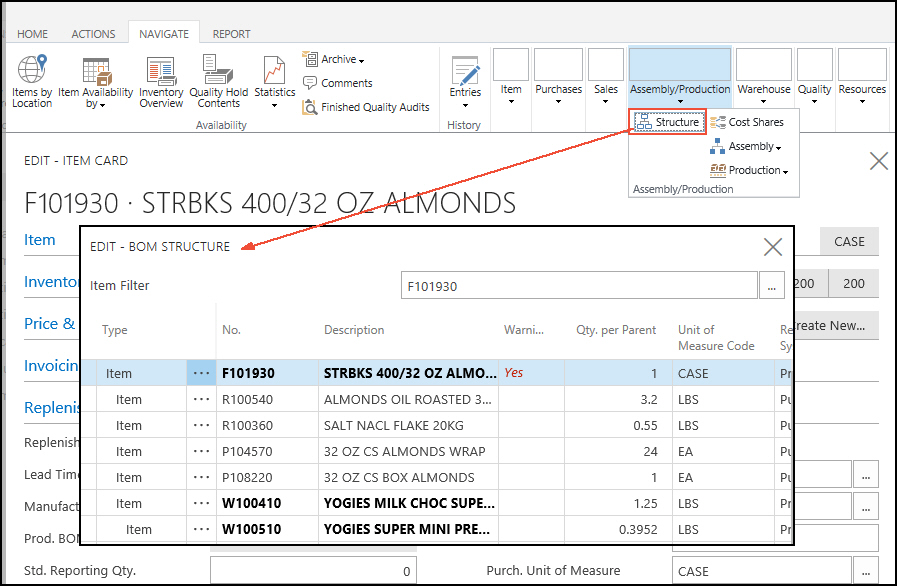

The finished good item F101930 has a BOM that includes a WIP item W100410.

The W100410 item also includes a WIP item W100510.

The F101930 item and W100410 item are considered downstream items.

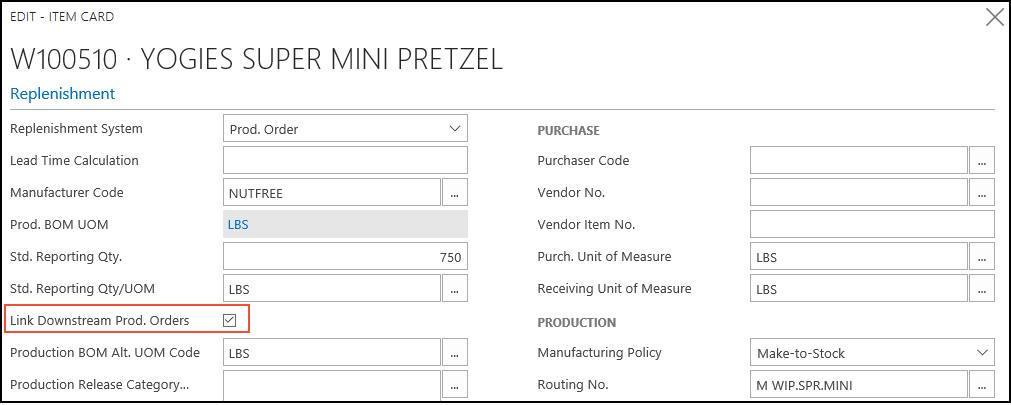

The Link Downstream Prod. Orders check box was selected on the Item Card for the W100510 item.

This setup means that production orders for the W100510 item are linked to production orders for the W100410 item.

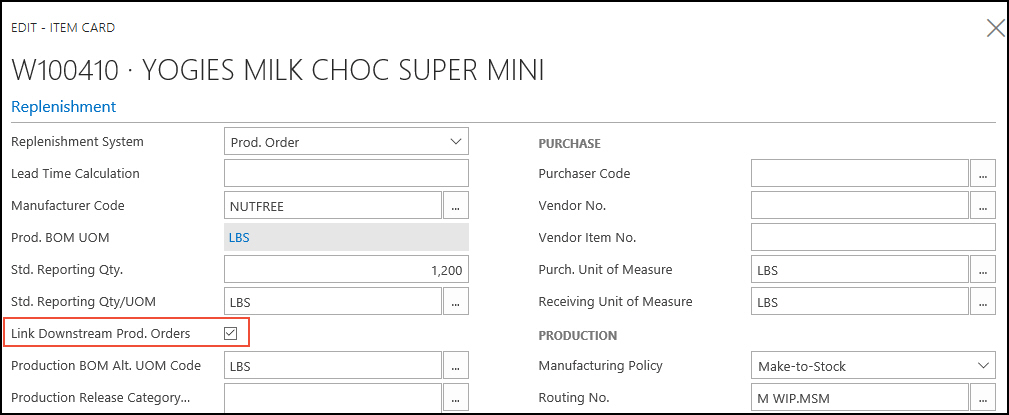

The Link Downstream Prod. Orders check box was selected on the Item Card for the W100410 item.

This setup means that production orders for the W100410 item are linked to production orders for the F101930 item.

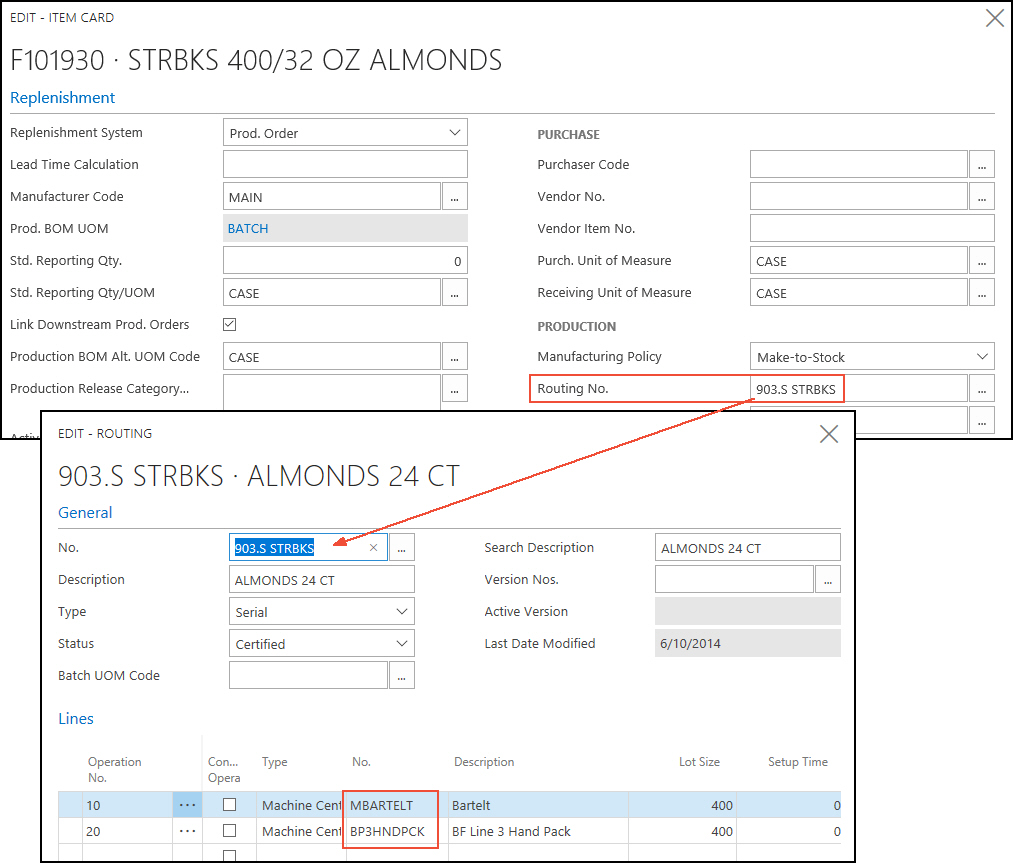

The F101930 item uses the 903.S STRBKS routing. The 903.S STRBKS routing uses the following machine centers:

MBARTELT

BP3HNDPCK

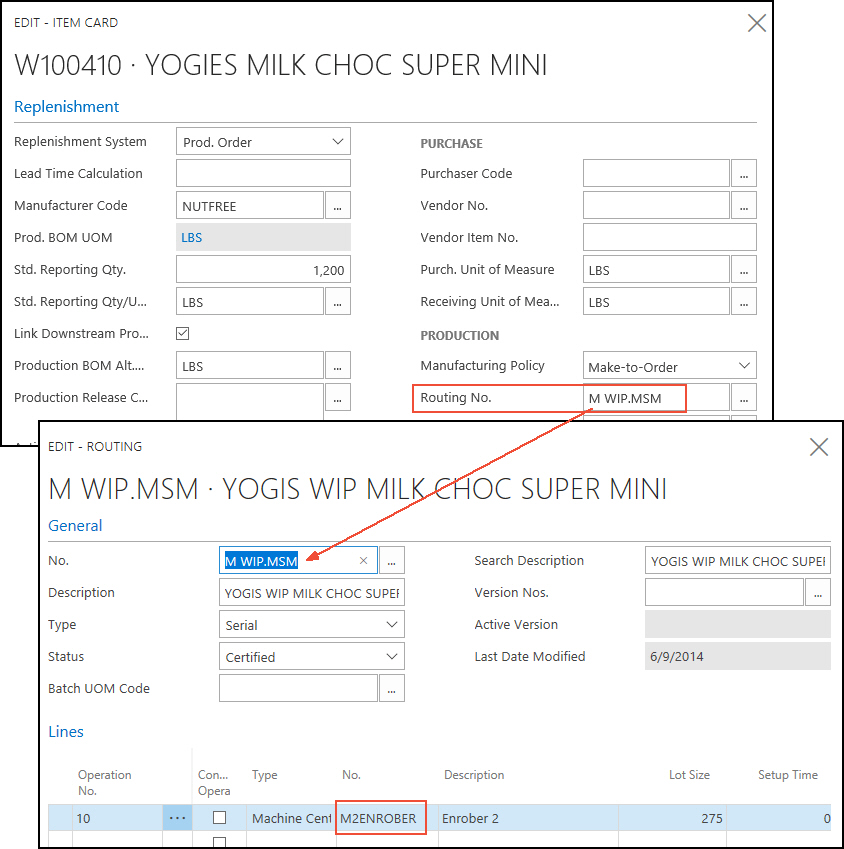

The W100410 item uses the M WIP.MSM routing. The M WIP.MSM routing uses the machine center M2ENROBER.

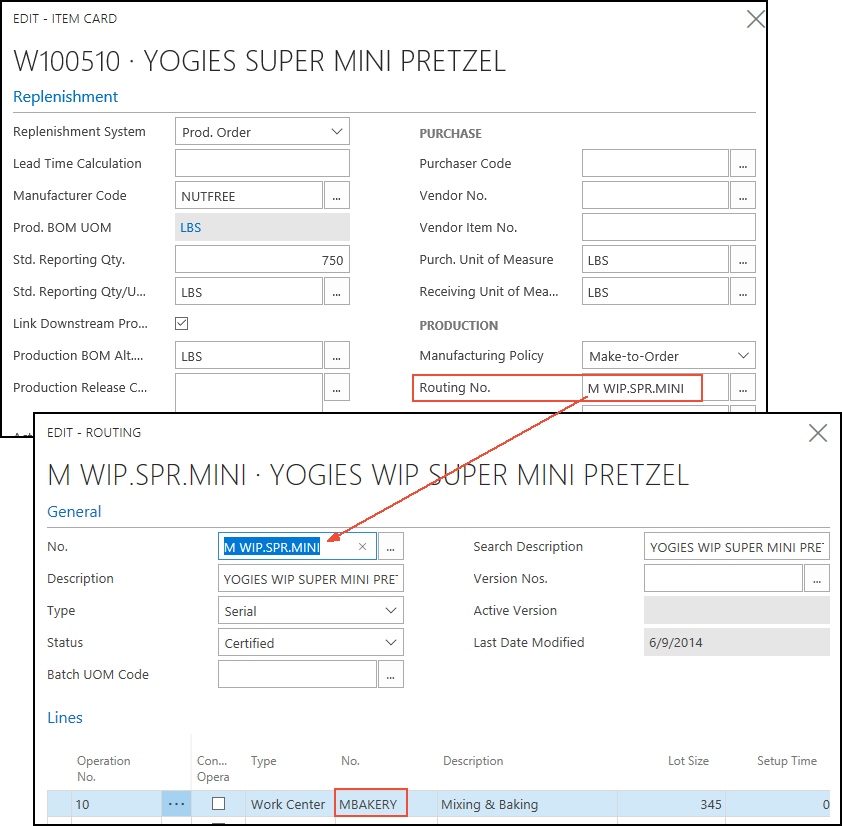

The W100510 item uses the M WIP.SPR.MINI routing. The M WIP.SPR.MINI routing uses the machine center MBAKERY.

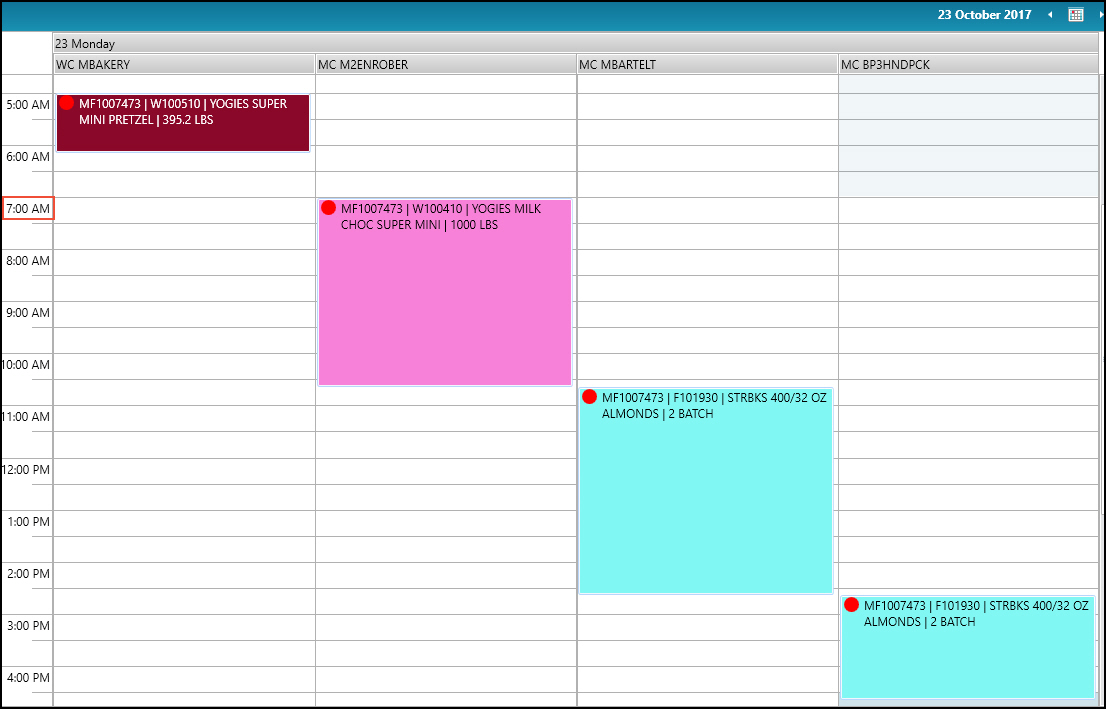

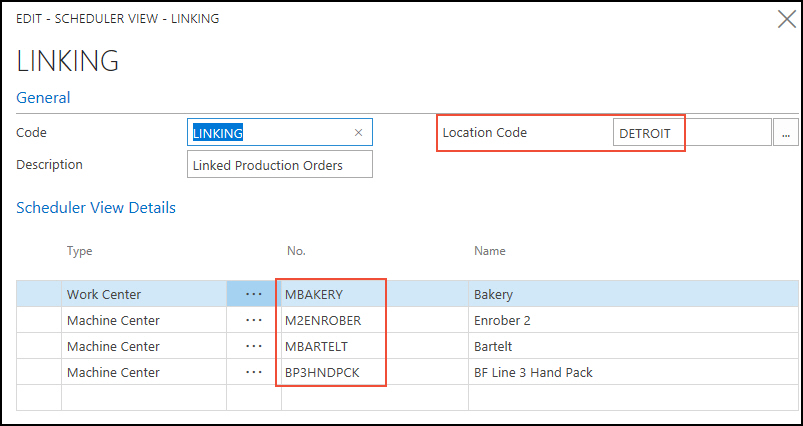

A Scheduler view is set up for the following machine centers:

MBAKERY

M2ENROBER

MBARTELT

BP3HNDPCK

The location is set to DETROIT.

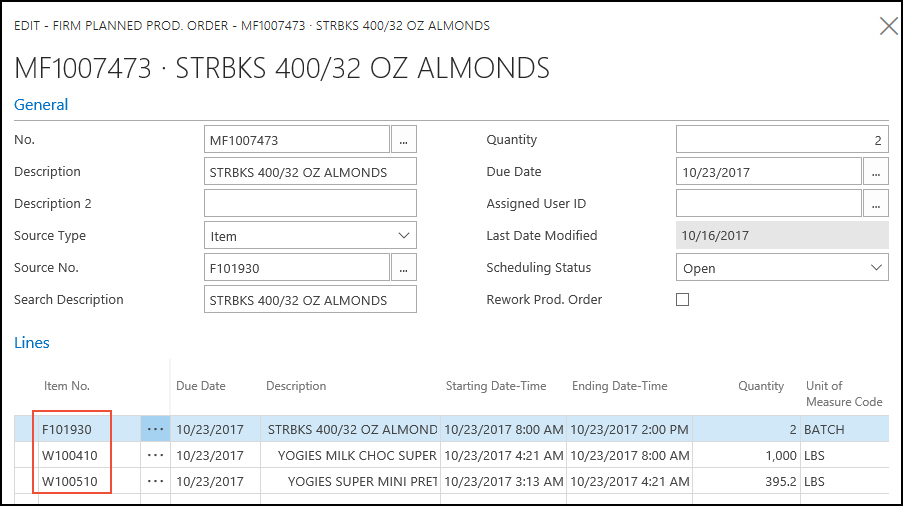

A production order was created for the F101930 item, which created lines for the linked items W100410 and W100510.

The location was set to DETROIT.

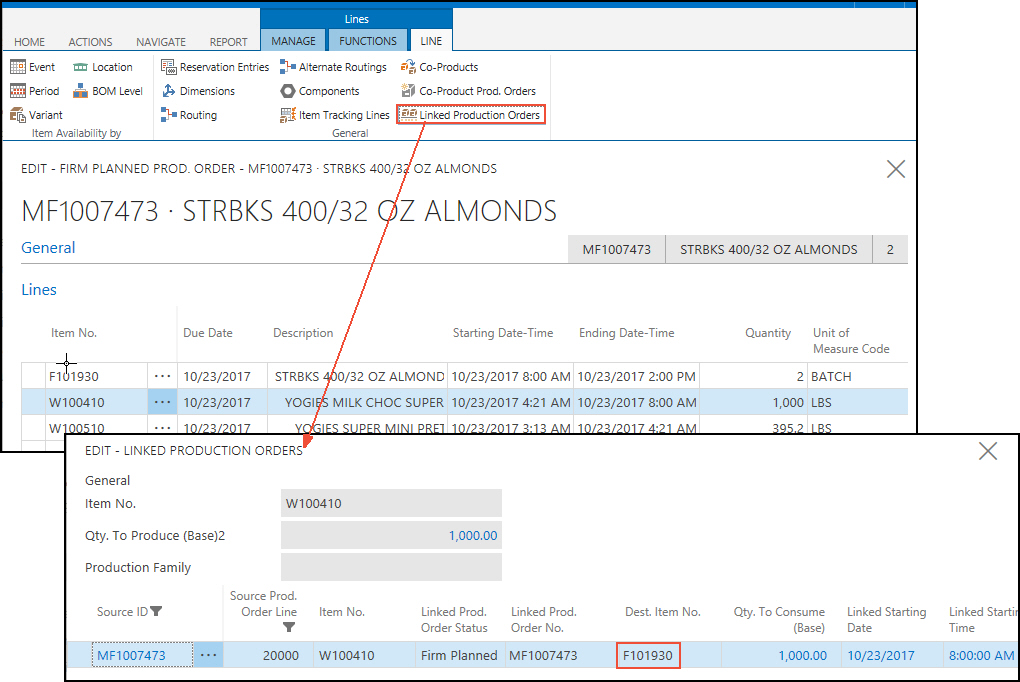

From the W100410 line, you can see that it is linked to the F101930 item.

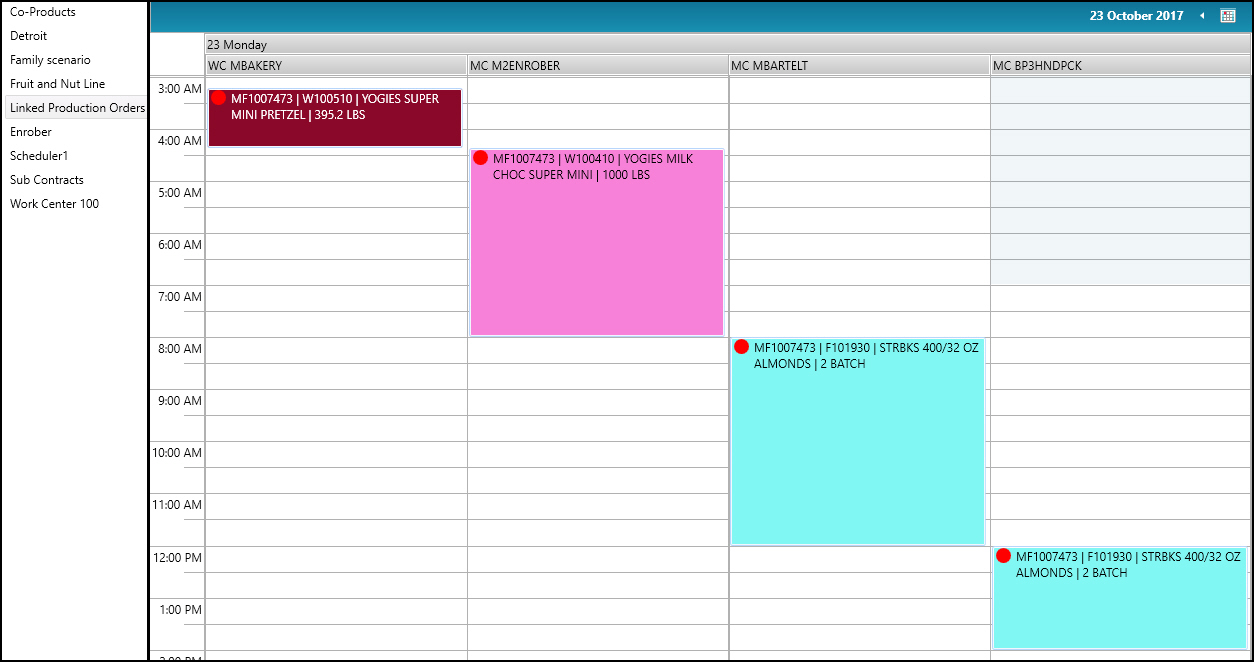

On the Scheduler, you can see that the production order is for 3 items, and is spread across 4 centers starting at 3:13am on Monday, October 23.

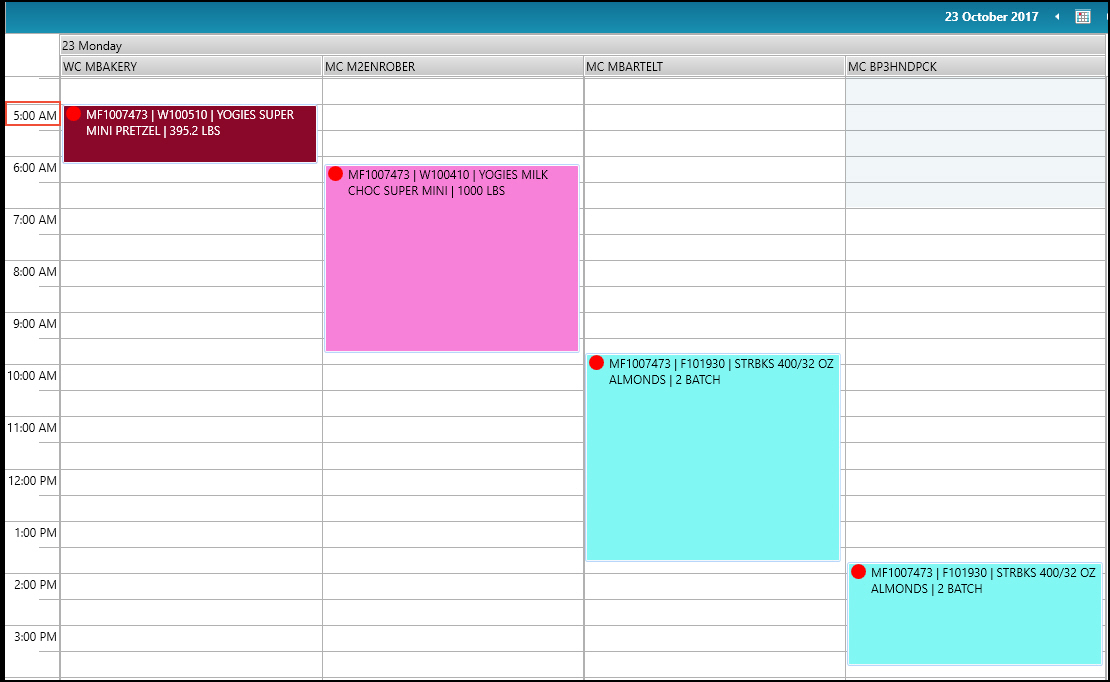

In the Scheduler, if you move a production order, the downstream production orders also move.

For example, when you move MF1007473|W100510 (burgundy) to start at 5am, the MF1007473|W100410 (pink) and MF1007473|F101930 (blue) production orders are automatically moved.

If you move the MF1007449|W100410 (pink) production order to 7am, only the MF1007448|F101930 (blue) production order automatically moves.

The MF1007450|W100510 (burgundy) production order is not moved because it is not downstream of the MF1007449|W100410 (pink) production order.