Walkthrough: Line Routing

The following walkthrough is an example of how in instances where a production order is spread across different centers, and one operation of the production order in the calendar is moved, the other operations are also moved.

This walkthrough is for customers who set up their routing so that the item goes through different types of centers.

Walkthrough

In JustFood, the F101850 item uses the BF802STBKS routing. The BF802STBKS routing goes through the following machine centers:

BFL1SIGBLEND

M1HAYSSEN

BP1HNDPCK

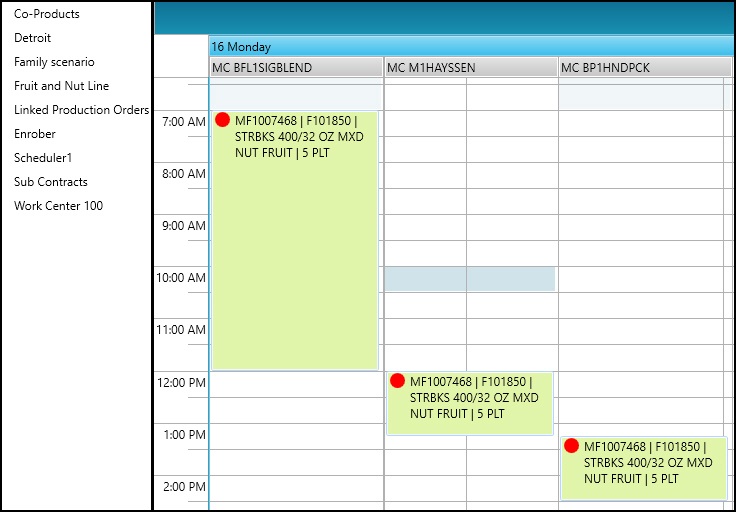

A Scheduler view is set up for the BFL1SIGBLEND, M1HAYSSEN, and BP1HNDPCK machine centers. The location is set to DETROIT.

A Production Order was created for the F101850 item. The Location Code was set to DETROIT. DETROIT is the location that is associated with the FRT_NUT_LINE Scheduler view.

In Scheduler, you can see that the production order is spread across 3 machine centers starting at 7am.

If you drag and drop any operation of the production order to another time, the rest of the production order is adjusted accordingly.

For example, the production order on BFL1SIGBLEND was moved to start at 10 AM. The operations for M1HAYSSEN and BP1HNDPCK were automatically moved as well.